TX500P-3200DS

3.2 m-wide Direct Sublimation Inkjet Printer

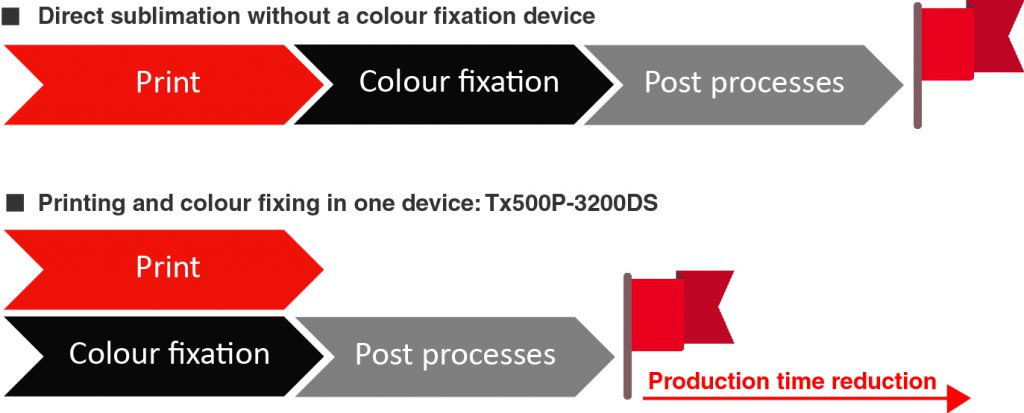

The TX500P-3200DS printer significantly reduces production time through its simultaneous performance of two operations, printing and colour fixation, reducing two steps to one. At a print speed of up to 130 m2 per hour, the TX500P-3200DS is ideal for production of samples as well as large lot production with short delivery times. It’s uniquely suited for a wide array of textile printing, including soft signage, customised apparel, and fabrics for home décor and furnishings.

|

|

|

|

Create…

Tapestry, Flags, Sports Apparel, Interior Fabrics, Fashion Textile and much more…

Specifications

| Print heads | On-demand piezo head (12 print heads in 3-line staggered configuration) | |

| Print resolution | Selectable: X-axis: 360dpi, 540 dpi, 720 dpi, 1,080dpi Y-axis: 540 dpi, 720 dpi | |

| Maximum print width | 3,290 mm (129.5 in) | |

| Maximum media width | 3,300 mm (129.9 in) | |

| Media thickness | 1.0 mm or less | |

| Roll Weight | 130 kg (286.6 lb) or less | |

| Roll outer diameter | 300 mm (11.8 in) or less | |

| Built-in Fixation Heater | Temperature | Standard: 180° C (356° F) Maximum temperature: 200° C (392° F) Temperature fluctuation: ±5° C (±41° F) |

| Transportation/ Heating Method | Vertical non-contact heating system | |

| Ink | Type/ Colour | Sb320/Bl, M, Y, K, LBl, LM |

| Packaging | 2-litre bottle (Large 3-litre ink containers are installed in the ink supply unit) | |

| Ink Set | 4-colour: Bl, M, Y, K 6-colour: Bl, M, Y, K, LBl, LM | |

| Interface | Ethernet 1000 Base T /USB 2.0 high speed | |

| Certifications | VCCI class A, FCC class A, ETL UL 60950-1 CE Marking (EMC, Low voltage, Machinery directive, and RoHS), CB, REACH | |

| Power supply | Main unit: Single-phase AC200-240V±10%, 50/60Hz±1Hz, 29A or less Fixation heater: Three-phase: AC200V±10%, 50/60Hz±1Hz, 50kVA or less | |

| Power consumption | Main unit: 7 kVA or less Fixation heater: 50 kVA or less (When using 200V) | |

| Operational environment | Temperature: 20–30 °C (68–86 °F) Humidity: 35–65 %Rh (No condensation) Recommended temperature range for stable operation: 20–25 °C (68–77 °F) Allowable range of temperature change: ±10° C (50° F) /hour or less Dust level: 0.15mg/m2 or less (Equivalent to a general office environment) | |

| Dimensions (W×D×H) | Main unit: 5,620 mm × 3,050 mm × 1,820 mm (221.3 in × 120.1 in × 71.7 in) Ink supply unit: 960 mm × 510 mm × 730 mm (37.8 in × 20.1 in × 28.7 in) Inverter: 910 mm × 600 mm × 1,240 mm (35.8 in × 23.6 in × 48.8 in) | |

| Weight | Main unit: 2,390 kg (5,269 lb) Ink supply unit: 30 kg (66.1 lb) Inverter: 140 kg (308.6lb) | |

All TX500P-3200DS inks are ECO PASSPORT by OEKO-TEX® certified.

Features of TX500P-3200DS

Printing and color fixation occur in a single printer unit

The Tx500P-3200DS contains a heating device that allows simultaneous printing and color fixation. Further, in order to deliver optimum finish, the printer and the heater units are linked. The printer starts printing when the heater reaches the optimum temperature. This novel feature considerably reduces production time and expands business opportunities by accommodating demands from sample creation to large-lot print production.

The maximum printing speed (130 m2/h)* enables high productivity

Reliable structure and technique achieves speed printing

Stable textile transportation assures accurate printing

New AMF (*) is installed in the feeding and take-up units to secure the stable textile feeding of the rolled media (width: 3.2 m, weight: 130 kg) and minimize textile shrinkage after heating. Furthermore, a pulling roller smooths polyester fabrics, which have the tendency to wrinkle. These features maintain an appropriate tension in the textile throughout the printing process to deliver excellent print results.

* The AMF applies an appropriate tension to the textile through a tension bar.

Waveform control technique assures beautiful printing

Each ink color has its own specific gravity and viscosity. To achieve precise placement of ink droplets onto the media, Mimaki designed an optimum waveform that allows the printhead to jet each ink color at the appropriate jetting angle without losing high ink droplet circularity even at a high head gap. Moreover, various ink droplet sizes can be precisely placed from a minimum of 6pl to a maximum of 24pl. Small droplets create beautiful high-resolution printing results, while large droplets are very useful for high-speed printing. Thus, Tx500P-3200DS satisfies a wide range of needs including beautiful high-quality printing and productive high-speed printing.

MAPS4 delivers stable high-quality printing

Swath boundaries are generally straight lines; therefore, a slight misalignment between boundaries causes banding or uneven color printing. MAPS4 reduces banding and uneven color printing with blurred boundaries similar to gradation printing.

Uninterrupted printing solutions

Ink and media shortage, clogged nozzles, and other minor problems influence stable productivity. The Tx500P-3200DS fully supports continuous printing with reliable technologies.

NCU automatically detects and recovers clogged nozzles

Clogged nozzles are detected automatically by monitoring ink droplets with sensors. When clogged nozzles are located, these are automatically cleaned, reducing waste printing. Nozzles are checked per transfer file.

NRS continues printing operations

If the clogged nozzles are not recovered after cleaning through the NCU function, the NRS selects substitute nozzles and then restarts printing. This is a significant novelty, since previously, when nozzle cleaning fails, the printhead has to be repaired by a technician, and the printing operation ceases until the printhead is repaired. The NRS allows the printer to continue printing without interruption by using non-defective nozzles as substitutes for defective nozzles until the technician arrives.*

* NRS may not be activated depending on print modes.

>> Click on image to enlarge it.

Ink supply unit enables long-time continuous printing

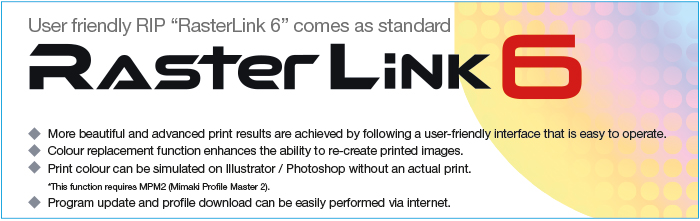

Software

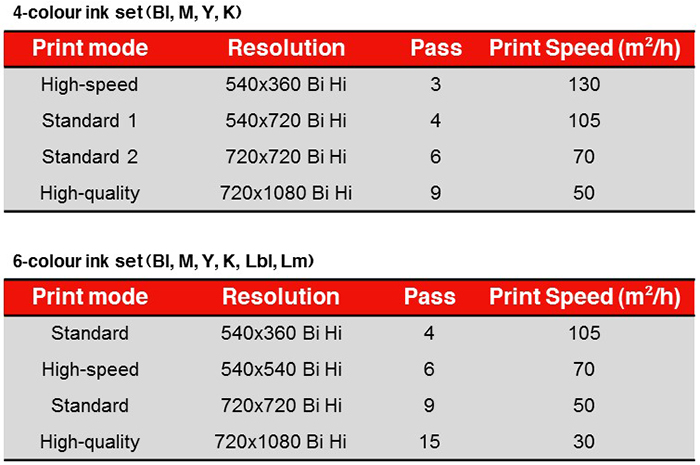

TxLink3 Professional or RasterLink6 is bundled according to user’s request.

All TX500P-3200DS inks are ECO PASSPORT by OEKO-TEX® certified.